Quick Answer: How to Embroider on Fleece?

Learning how to embroider on fleece will take patience, the right tools, and technique. Since fleece is soft and stretchy while shifting easily, it needs stabilization. Use a cutaway stabilizer only, sharp embroidery needles, and avoid designs that are too dense to the extent of distorting the fabric.

Hoop the fleece gently, applying no stretch to it, and set your machine tension accordingly for an even stitch. Whether personalizing cozy garments or custom gifts made from fleece blankets wholesale, knowing how to embroider on fleece will ensure durability and professional finishes every time.

Now let’s dive deeper.

The Art of Embroidering on Fleece

One of the coziest and most versatile fabrics of today is fleece—great for making warm hoodies and jackets, as well as for home décor and blankets. But embroidery and fleece, they don’t really go hand in hand most of the time. Its plush surface and slight stretch cause puckering and misalignment if unprofessionally dealt with.

Anytime you are personalizing, Embroidering on fleece entails sitting with either a script monogram, a logo, or some fancy stitching to create beautiful, imperishable designs without causing any damage to the fabric. Below is a complete guide from stabilizer and needle choice to machine adjustment and project finishing for the pros to follow.

1. Knowing What Fleece Really is

Before jumping into the embroidering process, understanding the fabric you are working with is of utmost importance. Fiber Characteristics:

- Stretches and soft: It stretches a little, especially cross sectional, making fleece quite comfortable and delicate to needle.

- Lofty Texture: Due to its nap-the raised fibers-fleece stays warm and feels soft, but threads do tend to sink in.

- Synthetic Fiber Base: It is usually made of polyester; this, of course, reacts differently with heat and tension as opposed to cotton or linen.

Due to these characteristics, fleece embroidery requires a much gentler and well-stabilized approach that can prevent distortion and damage.

2. Tools and Materials You’ll Need

You have the materials, and half the job is done. For a professional finish, source the following:

a. Stabilizer

For fleece, a cutaway stabilizer is ideal since it supports the fabric through stitching and washing. Steer clear from tear-away kinds as they tend to shift during stitching or distort the fabric when taken away.

For an added layer of surface protection, use a water-soluble topping. This prevents stitches from sinking into the fleece pile and keeps your embroidery crisp.

b. Needles

You want to use a ballpoint or a universal embroidery needle in sizes 75/11 or 80/12. A ballpoint needle glides between fibers instead of piercing them, reducing the incidence of snags and holes.

c. Thread

This thread has to be of great quality, polyester preferably, for strength, colorfastness, and flexibility so that it moves with the fabric. Rayon threads, too, can work for lighter designs.

d. Hooping and Machine Settings

Choose an embroidery hoop large enough to keep the design nice and flat but not so tight that it stretches the fleece. Set your machine’s tension and speed to medium tension and slow stitching for better control and clean lines.

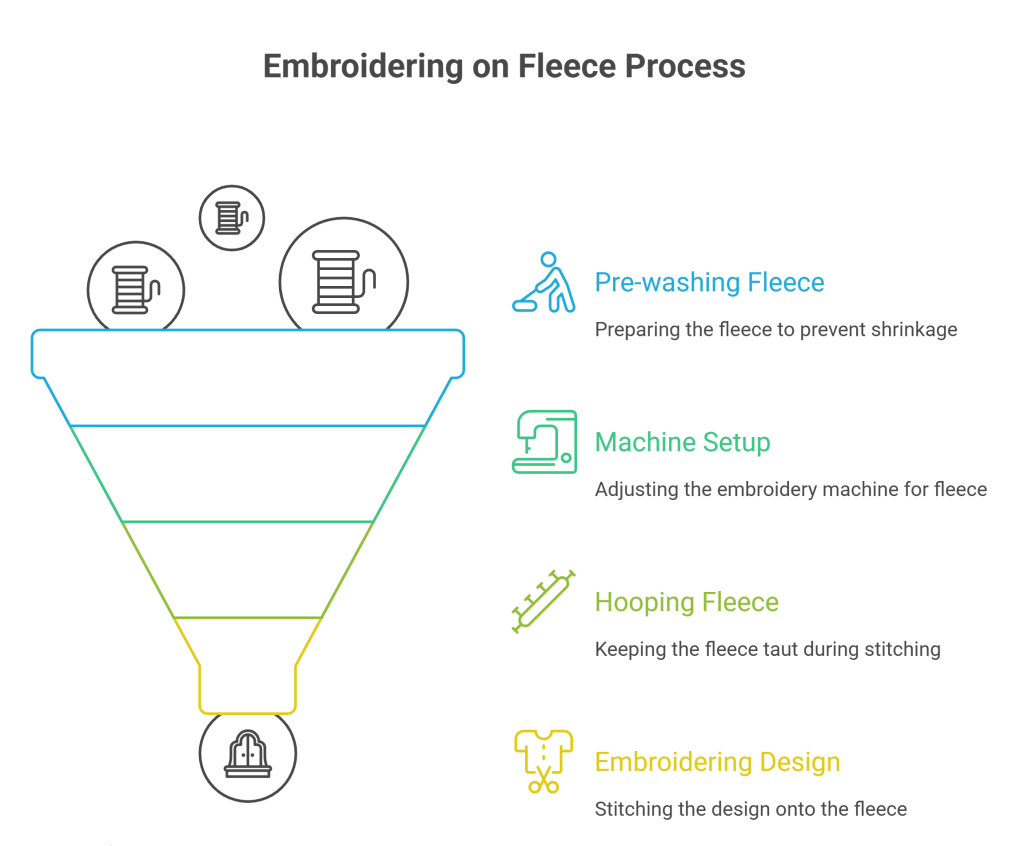

3. Preparing Your Fleece for Embroidery

Doing it right will avoid most embroidery disasters.

Step 1: Pre-Wash the Fabric

Fleece may or may not shrink as cotton does; a wash will remove surface lint and factory residues. This will facilitate the better bonding of the stabilizer to the fabric and then cleaner stitches.

Step 2: Cut the Stabilizer

Cut a piece of stabilizer just a bit larger than your hoop. If you work on thicker fleece or rather large designs, double up the stabilizer for extra support.

Step 3: Mark Your Design Area

Make sure to outline the embroidery area with a fabric-safe marking pen or chalk. Avoid using any ink that can bleed or mark polyester forever.

Step 4: Hoop the Fabric

With the stabilizer underneath, align it carefully before hooping. The fleece should be taut but never stretched for puckering will appear when the fabric relaxes later.

4. Stitching Tips for Perfect Results

1. Use a Topping Layer

For best results, a water-soluble stabilizer is applied on top of the fleece before stitching. This layer prevents the threads from sinking into the nap and creates crisp, raised designs.

2. Select the Right Design

Avoid very dense fills or tiny details that press down fleece fibers or distort the design. Open, satin, or light fill stitches are the best.

3. Adjust Stitch Density

Slightly reduce stitch density versus embroidery on regular fabrics. By doing so, the design sits on fleece in a natural manner, without making the texture hard and bulky.

4. Slow Your Machine Down

Set your embroidery machine to a slower speed, something between 600 and 700 stitches per minute. It will make the embroidery more accurate, while also reducing thread breakages.

5. Keep Checking Your Fabric

Pause now and then to check the tension, stitch balance, and alignment. If small problems are spotted early enough, starting all over again can be avoided.

5. Removing the Stabilizers

The last step after the stitching process is stabilizer removal.

- Cutaway stabilizer (back): Trim as much excess as possible close to the design, leaving about ¼ inch around the stitches for long-term stability.

- Water-soluble topping (front): Tear the excess off gently, then blot with a damp cloth to remove any residues.

Do not iron fleece directly; heat will melt the fibers. If needed, press from the wrong side with a pressing cloth and low heat.

6. Personalizing Fleece Blankets

Embroidery on fleece is not just for clothes but also for personalizing gifts, building a brand name, or enhancing items for sale, such as custom blankets.

For businesses buying fleece blankets wholesale, embroidery gives added value and brand identity. Company logos or initials may be stitched on with a custom message to make promotional pieces or retail-ready pieces.

Buying in fleece blankets bulk is ideal for customization because it is economical, of consistent quality, and available in many colors and sizes. Adding embroidery will transform these into classy keepsakes for corporate occasions, schools, sports teams, or even gifts for the holidays.

7. Concepts for Embroidered Fleece Projects

Let me turn the billion dollar ideas into action for your embroidery skills on fleece:

- Personalized Baby Blankets: Add the names, birthdates, or even cute motifs.

- Corporate Gifts: Log in embroidery on fleece throws for employee appreciation events.

- Pet Accessories: Make cozy embroidered mats or blankets for pets.

- Holiday Decorations: Stitch seasonal designs on throws and stockings.

- Team Apparel: Embroider team names or logos on hoodies and jackets.

The soft texture and low price of fleece make it ideal for either personal or commercial projects.

8. Troubleshooting Common Embroidery Problems

Sometimes problems happen, despite the best preparation on fleece. Here are some solutions:

Problem 1: Fabric Puckering

- Causal Factor: The fabric was stretched too tightly inside the hoop.

- Solution: Re-hoop gently, and use a firmer stabilizer.

Problem 2: Stitches Sinking Into Fabric

- Causal Factor: No topping or wrong tension.

- Fix: Use a water-soluble finishing and reduce stitch density a little.

Problem 3: Broken Thread

- Cause: Dull needle or incorrect speed.

- Fix: Change the needle and slow down the machine.

Problem 4: Distorted Design

- Cause: Unbalanced tension or a flimsy stabilizer.

- Fix: Tighten bobbin tension or use a heavier cutaway stabilizer.

9. Why Fleece Embroidery Must Be Learned?

Fleece embroidery offers both artistic and business perspectives. It merges warmth and style with personal expression or branding. Fleece items still stand the test of time from personalized gifts to retail collections.

In turn, customized fleece items, mainly blankets, offer a thriving opening for small-scale businesses and embroidery studios. Purchasing fleece blankets wholesale or in fleece blankets bulk in themselves provide a consistent base for custom-made work that allows you to tailor to demand without sacrificing quality or profit.

Final Thoughts

Knowing your way around how to embroider on fleece would open up a fairly good number of creative avenues-from unique gifts to profit-oriented custom products. Right from stabilizers and needles to machine settings, everything will be adjusted in such a way that the embroidery does not just turn out looking crisp and professional, it does so without compromising on the softness of the fleece.

If you work for yourself or buy commercially, fleece ranks very high as a fabric to work with and have fun. Wholesale fleece blanket suppliers manufacture into great uses for increasing niche offerings if anything is custom products at scale. Proper methods and materials go into making a great fleece creation that will look exquisite with embroidery, feel amazingly soft, and stay for years.

Leave a comment