- It All Starts with the Right Material

- The Step That Makes It Feel Like Fleece

- Why Some Fleece Blankets Feel Better Than Others

- Sustainability in Modern Fleece Making

- Bringing It All Back to Real Life

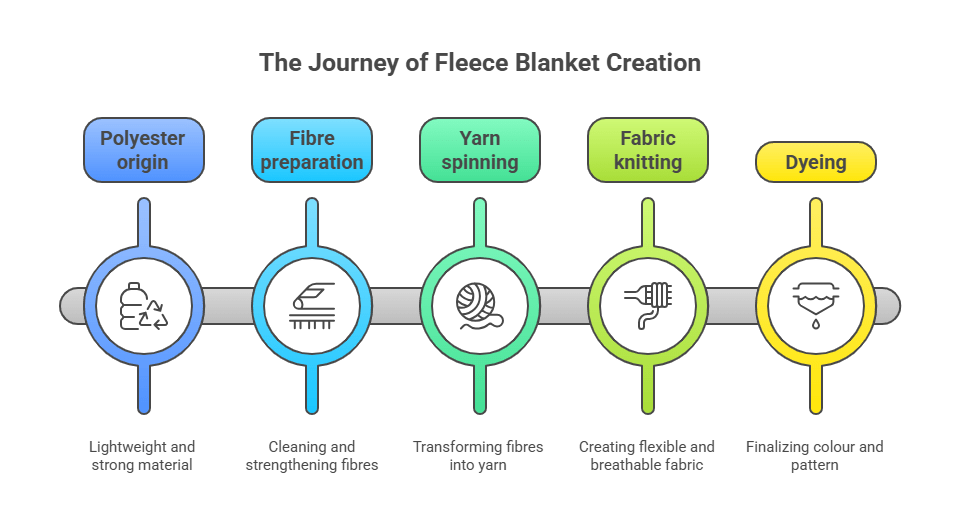

Fleece blankets are made by the process of converting the polyester fibres, frequently made in recycled form, into yarn, closely knitting the yarn into fabric, and then carefully brushing and finishing the surface, resulting in a soft and fluffy texture that we all enjoy. When the fabric is properly finished, it is cut, cleaned, again, and inspected for suit before being made up for use in making something cosy.

If you have tried wrapping a fleece around you and thinking, “How fleece blankets are made?” indeed, you are not alone. To make fleece, many processes have toiled away that most people are unable to see, and it until you come to appreciate it to an extent that you will feel drawn toward. Let us go along with how fleece blankets are made, step-by-step, yet in one easy way, plus with mutual respect.

It All Starts with the Right Material

Polyester is a likely origin for most of the fleece blankets. It sounds scientific, but it relates to the practical side of things. Being lightweight, this is a really helpful fabric. Through its strength, polyester keeps the user warm. In certain sectors, polyester for fleece is obtained from recycled plastics, so waste is saved significantly while something is turned out, which is very nice.

These raw materials are prepared and cleaned before they’re turned into fibres. At this stage, nothing looks soft yet—it’s more about creating a strong foundation that will later become comfortable and durable.

Turning Fibres into Yarn

Once the material is prepared, it is transformed into thin fibres; these fibres are stretched and spun into yarn, exactly how thread is also made. The quality of the yarn is of great paramount importance. Smooth yarn makes for a consistent fleece feel that is soft, pills little, and remains durable through frequent usage and washing.

When the yarn is placed down incorrectly, the finished product will always be unsatisfactory, analogous in importance to the spine of an object.

From Yarn to Fabric

Knitting new fabric out of yarn is the next step. Unlike stiff fabrics built from weaves, fleece is knitted, resulting in a fabric that is flexible and breathable. Right now, this fabric does not, however, look like the fleece that we come to know. It is fairly smooth; another term sometimes used for it is “unfinished” fabric.

Dyeing of the cloth is done to finalise its colour or pattern. The colouring is the beginning of the fleeces taking on their own shade, be it the shade or the print design.

The Step That Makes It Feel Like Fleece

This is where the magic really happens. To create the signature softness, the fabric goes through a brushing process. Special machines gently lift tiny fibres from the surface, creating that fuzzy, plush feel. This step is often repeated to make sure both sides feel equally soft.

After brushing, the fabric is closely sheared to make the fibres even and smooth. After that, heat is passed over carefully to help weld the fibres together. This final process is towards shedding and keeps the fleece looking good over a period.

Turning Fabric into a Blanket

When the fleece fabric is finished further, it is then cut into a size pattern for a blanket. The edges are then finished to prevent fraying and provide the blanket with a neat and durable appearance. While some blankets are sewn, other varieties have edges of different styles depending on the design.

This stage is all about shaping the fleece into something practical and ready for everyday use.

Cleaning and Quality Checks

During manufacturing, stray fibres are bound to manifest. It’s cleaned off to pave the way for the initial use in order to help prevent pilling, leading to fewer stray threads during the first usage.

To make sure that the size, fabric, finish, and folding meet the quality standards of each fabric used to produce these blankets, each blanket is inspected before the manufacturing process. This approval is a measure necessary to guarantee both comfort and longevity by eliminating minor deficiencies.

Why Some Fleece Blankets Feel Better Than Others

If you’ve ever felt that not all fleece blankets are the same, it’s due to a production approach, usually involving yarn quality, fabric weight, and more combed repetitions and carefully applied finishing. When all of these steps are well and consciously done, the result will be a throw suitable for everyday use, being soft, cosy, and very warm in a matter of time.

The understanding of the fleece blanket-making process helps make it clear how good fleece feels and how easy it is to use, as it is designed in that way.

Sustainability in Modern Fleece Making

Nowadays, a good sign of a fleece blanket is the use of sustainable materials, such as recycled and durable ones, with an eye to saving waste and life span. If a fleece blanket is thoughtfully tailored and purchased keeping energy efficiency in mind, it suggests that its replacement need not occur very soon; this integration is good for a home and even for environmental motivators.

Bringing It All Back to Real Life

In the end, fleece blankets come to be lived in. They make them with warmth that is not weighty, softness without fragility, and easy care with no mollycoddling. Therefore, in the whole fleece-to-throw process, every dimension serves the ultimate cooking of comfort for a living heat.

The manufacturing of our fleece blankets is careful regarding the materials used and the finishing methods. The main emphasis is on the softness, durability, and responsible making process. As a part of our wholesale fleece blanket offerings, we extend these well-made blankets into homes, retail units, and entities that value comfort righteously.

So, the next time you wrap yourself up in a fleece blanket, you will know that the warmth that burns you is much more. More has gone into it than just cuddly fabric. More, really, is what makes every day snug even during such dark times.